Display various 3D sintering ceramic shapes of additional manufacturing 3D ceramics (calcium phosphate, alumina, zirconia, etc.). In addition to the medical field, it will also have great potential applications in the aerospace and semiconductorr industries.

Prof. Chih-Kuang Wang’s research team has designed a novel osteochondral double-layer scaffold. The lower layer of the double-layer scaffold uses a three-dimensional (3D) printed β-tricalcium phosphate (β-TCP) bioceramic scaffold. The scaffold utilizes digital light processing (DLP) technology and a patented photo-cured and negative thermoresponsive (NTR) bifunctional bioceramic slurry. This 3D bioceramic scaffold not only provides the necessary mechanical support for the regeneration of subchondral bone tissue but also delays its biodegradation and offers a stable matrix for cartilage regeneration.

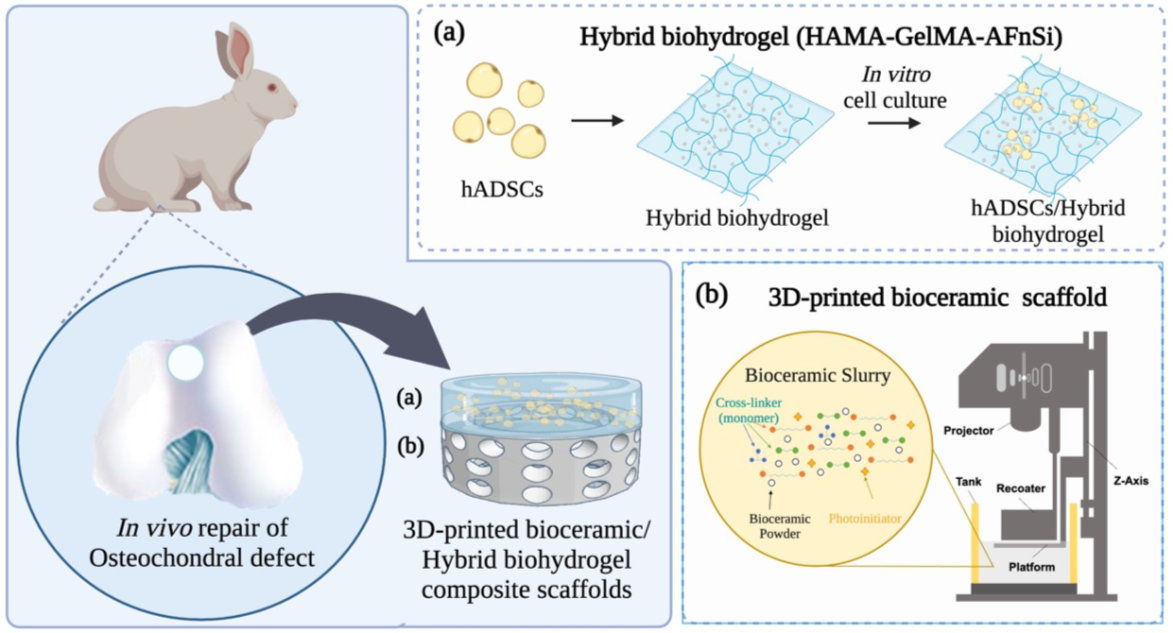

The upper layer of the double-layer scaffold is a 3D bioinspiral hybrid hydrogel, mainly composed of hyaluronic acid methacryloyl (HAMA) and gelatin methacryloyl (GelMA) copolymers. Acrylate functionalized nano-silica (AFnSi) is innovatively used to enhance the mechanical properties of the hybrid light-cured hydrogel and slow down its degradation rate. In vitro studies indicated its excellent cytocompatibility and ability to promote cartilage differentiation. The team has applied for a patent for this hybrid light-curing biohydrogel system for cartilage generation (ROC patent number: 798084). The research results indicated that the double-layer osteochondral scaffold, composed of this 3D bioceramic scaffold and photo-cured hybrid hydrogel rich in human adipose stem cells (hADSCs), showed good osteochondral repair effects, accelerated bone formation and promoted fusion with adjacent bone tissue in a rabbit knee cartilage defect model. This research has confirmed that the 3D printing technology has broad application potential in the field of tissue repair. The team is fortunate to receive the NSTC’s Applied Research Incubation Grant (Cranial burr hole cover of 2021~2024) and successfully spun off a new start-up company, "Precisely Printed Medical Co., Ltd.". This company focuses on the development of active materials layer-fabricated 3D bioceramic bone graft substitutes for personalized bone defect indications, building upon this 3D bioceramic scaffold bone graft material product technology.

A schematic diagram of the well-integrated bilayer osteochondral scaffold is expected to guide stem cells' chondrogenic and osteogenic differentiation and provide a promising solution for osteochondral tissue repair. The human adipose-derived stem cell (hADSCs) laden photocured hybrid biohydrogel comprised of hyaluronic acid methacryloyl (HAMA)/gelatin methacryloyl (GelMA) (1/1) and 0.5% (w/v) acrylate-functionalized nano-silica (AFnSi) crosslinker, which provide a suitable environment for cartilage regeneration. a The concave-top disc structure of the subchondral scaffold with the denser intermediate layer and the well-open interpenetrating pore channels structure of the 3D-printed bioceramic scaffold is made using digital light processing (DLP) technology and the novel photocurable negative thermo-responsive (NTR) bioceramic slurry.

l Patent certified

1. Method for additive manufacturing of 3D-printed articles, WO(EP)-European Union, 3385057, 2021/02/24.

2. Method for additive manufacturing of 3D-printed articles, WO(CN)-China, 4274912, 2021/02/26.

3. Method for additive manufacturing of 3D-printed articles, WO(US)- United States, 111,111,84, 2021/09/07.

4. Slurry for photocuring 3D printing, preparation method therefor, and method of use thereof, PCT (CN)-China, 5682329, 2023/01/06.

5. Slurry for photocuring 3D printing, preparation method therefor, and method of use thereof, PCT (JP)-Japan, 7255915, 2023/04/03.

6. Inorganic nanosilica-crosslinker mixed with bio-ink to promote cartilage differentiation of adipose stem cells, ROC (Taiwan), I798084, 2023/04/01.

7. A skull repairing structure, ROC (Taiwan), M648441, 2023/11/21.

l Industry-government-academic cooperation project:

1. Adipose stem cells laden 3D-printed novel composite tissue-engineered tracheal grafts combined with tracheal luminal epithelial cell sheets for tracheal regeneration (II-III), National Science and Technology Council, 2024/08/01~2026/07/30 (1,660,000; 1,540,000 NT)。(NSTC 113-2314-B-037 -024 -MY2) (PI)

2. Evaluate the proliferation and differentiation activities of biohybrid hydrogel system and mesenchymal stem cells (MSCs), Industry-Academic Cooperation Project (順臻生物科技有限公司), 2022/09/01-2024/12/31. 15,000 NT) (PI)

3. Adipose stem cells laden 3D-printed novel composite tissue-engineered tracheal grafts combined with tracheal luminal epithelial cell sheets for tracheal regeneration (I), National Science and Technology Council, 2023/08/01~2024/07/30 (978,600 NT)。(NSTC 112-2314-B-037-078) (PI)

4. Industry Perspective - Applied Research Incubation Project―「Cranial burr hole cover of 3D bioceramic bone graft substitute using the additive manufacturing method (II)」, National Science and Technology Council, 2022/01/01至2024/03/31 (9,150,000 NT)。(NSTC 112-2622-B-037-001 -) (PI)

5. Industry Perspective - Applied Research Incubation Project―「Cranial burr hole cover of 3D bioceramic bone graft substitute using the additive manufacturing method (I)」, Ministry of Science and Technology, 2021/11/01至2022/12/31 (8,500,000 NT)。(MOST 110-2622-B-037-002 -) (PI)

6. Study on 3D bioprinting of tissue-engineered vascular grafts with novel bioinspired bioink, Ministry of Science and Technology, 2021/08/01至2022/07/30 (1,140,000 NT)。(MOST 110-2314-B-037-032) (PI)

【Research Team】

Team Members: Prof. Chih-Kuang Wang, Chih-Yun Lee, Li-Ann Chi, Jie-Ying Wang, Li-Fang Lin

Research Team Introduction: The team has three patents for negative temperature-sensitive bioceramics system that are deployed around the world. We have been committed to the development of " healing faster, and supportive 3D bioceramic aggregates" 3D printing technology. Precision bone graft substitutes for personalized bone healing with the primary mission of promoting human health and well-being.

Research Contacts Email: ckwang@kmu.edu.tw ;j020900@yahoo.com.tw

Video:https://www.youtube.com/watch?v=izCe6z3lQvY

Members of the R&D team of Precisely Printed Medical Co., Ltd. (Li-Fang Lin, Chih-Kuang Wang, Jie-Ying Wang, Chih-Yun Lee, Li-Ann Chi).

Vice President Bi-khim Hsiao attended the 2024 Taiwan International Medical and Health Care Exhibition. The Kaohsiung Medical University Pavilion attracted much attention. She also visited the new spin-off companies of Kaohsiung Medical University - Precisely Printed Medical Co., Ltd. and Cardio Metrics Co., Ltd.